Application of Inkjet Printing for Antenna in Package and Flexible Antenna

| Name | Year |

| Sheng-Xue Huang | 2021 |

| Keywords | |

| Additive manufacturing, inkjet printing, Antenna in Package, flexible antennas, substrate integrated waveguides |

In this thesis, inkjet-printing technology is demonstrated for multiple antenna applications, including substrate integrated waveguides (SIWs), antenna in package (AIP), and flexible substrates. In comparison with conventional printed circuit board (PCB) technology, inkjet printing shows advantages such as additive manufacturing, rapid prototyping, and suitability for flexible electronics. While numerous attempts have been made to advance the inkjet-printing technology, more studies should be carried out to improve the efficiency for the three aforementioned applications.

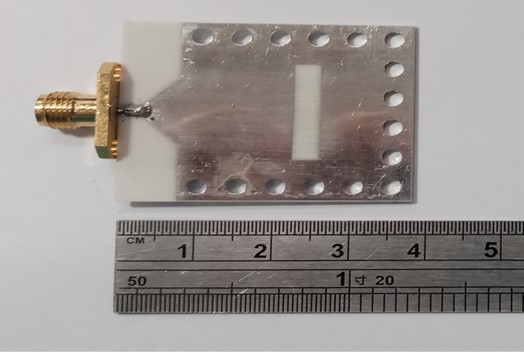

Regarding the SIW application, we propose a fully inkjet-printed fabrication technique that reduces the complexity and cost. To remove the additional fabrication procedure of shorting pins, earlier studies have employed CO2 laser to develop stepped-via holes; however, the shaping of the stepped hole topology requires high alignment sensitivity and the precise control of laser power level. In contrast, we demonstrate fully inkjet-printed vias by a mechanical approach without flipping the substrate. The proposed technique realizes the equivalent circuit model of a shorting pin by cylindrical-surface nanoparticles, and it is validated by different substrates, including RO 4003C and polyimide. The performance is demonstrated through two-port SIW circuits and SIW antennas.

Regarding the AIP application, we extend the fully inkjet-printing technique to the wire bonding. In AIP scenarios, interconnection using wire bond is widely used, whereas the performance is significantly influenced by the discontinuity introduced. To reduce the discontinuity and further enable a fabrication without additional assembly, we implement the inkjet-printing technology for the wire bonding. Along with the fully printable via holes, the efficiency of AIP fabrication and the performance can be enhanced. The capability of the inkjet-printing wire bonding is demonstrated through the test of continuity and relationship between current and voltage.

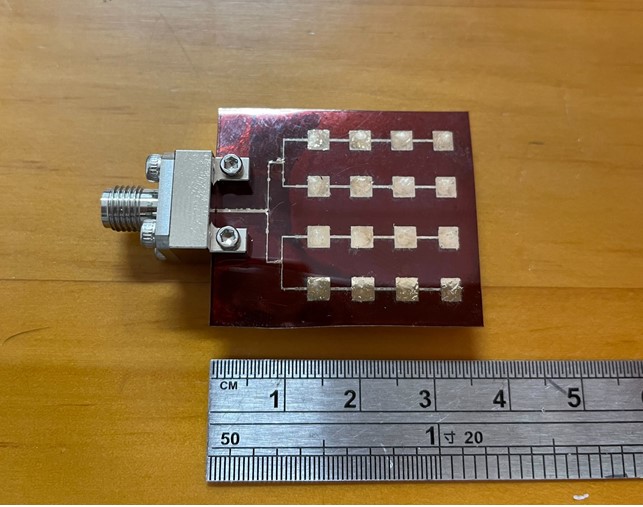

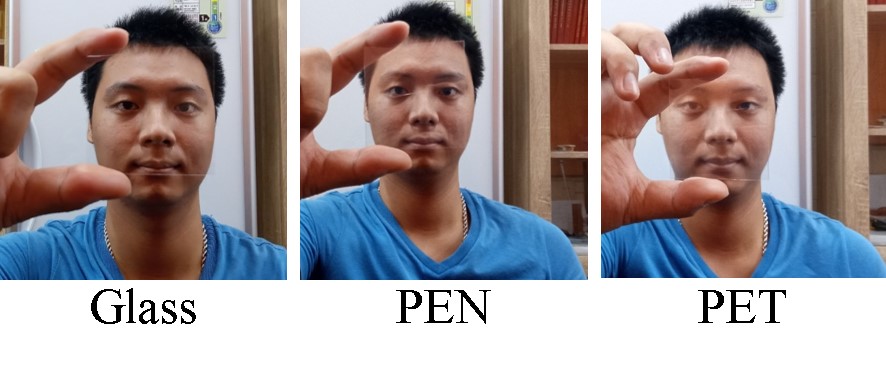

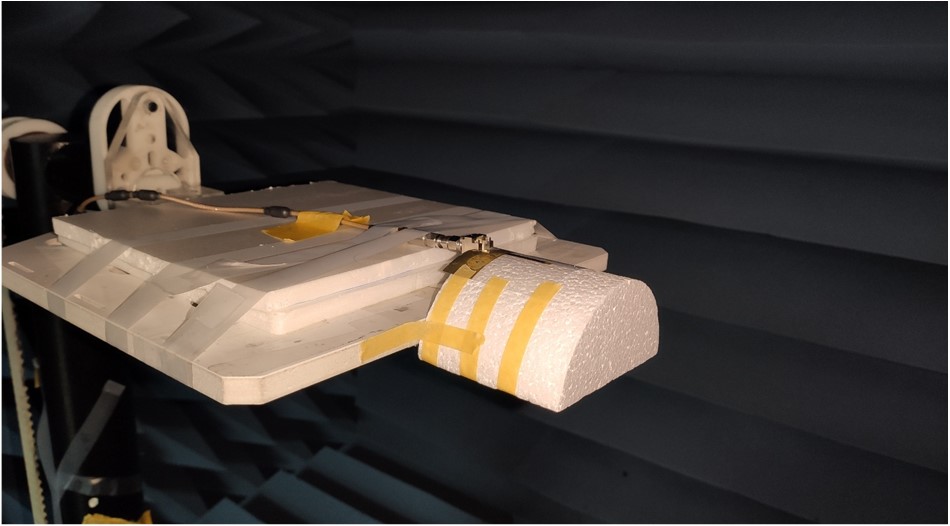

Finally, regarding the flexible substrate, we design and fabricate flexible monopole antennas and patch arrays. Although inkjet-printed flexible antennas have been widely reported in terms of one single element, relatively few studies propose inkjet-printed flexible antenna arrays. When multiple elements are excited as an array, flexible substrates rise to the challenge of a bending feeding network and the distortion of patterns. Thus, first of all, we use a monopole antenna to explain the fabrication and the test of flexibility, and then we design multiple patch arrays on polyimide and polyethylene naphthalate substrates. The antenna parameters including reflection coefficients, gain, efficiency, and patterns are reported to validate these designs.

Publications

Publications

- C.-C. Chung, F.-P. Lai, S.-X. Huang, and Y.-S. Chen, “Anisotropic metasurface with asymmetric propagation of electromagnetic waves and enhancements of antenna gain,” IEEE Access, vol. 9, pp. 90295–90305, 2021.

- Y.-S. Chen and S.-X. Huang, “Performance enhancements of fully inkjet-printing technology for antenna-in-package and substrate integrated waveguides,” Int. J. Antennas Propag., vol. 2022, pp. 1–14, Mar. 2022.